Miyanoue:

Large-scale tool production at a rich source of stone material. More than 770 items of refitted materials are reconstructed.

Pyramidal-point stone tools Latter half of the Upper Paleolithic, ca 20,000 - 18,000 BP. Length: (item at left) 5.1 cm; (item at right) 4.7 cm. Pyramidal-point stone tools are thought to have been spear heads, or tools for cutting. Finished items were made by retouching thick flakes. At the Miyanoue site they are mostly small products of around 4 - 5 cm in length. |

Refitted materials for pyramidal-point stone tools Latter half of the Upper Paleolithic, ca 20,000 - 18,000 BP. (Item at right front) Length: 5.0 cm; width: 7.9 cm; thickness: 3.3 cm. Because flakes of a certain thickness were suited for making pyramidal-point stone tools, it is seen that flaking was carried out by changing the point and angle of percussion appropriately to obtain the required thickness. The flaking technique was characterized by a relatively flexible style, with no determined sequence in particular. |

Miyanoue Site, Minamikyūshū City, Kagoshima Prefecture

A stone tool manufacturing site located at a raw material source

This is a stone tool manufacturing site of the latter half of the Upper Paleolithic (28,000 - 14,000 BP), located on top of a tableland 140 m in elevation in the central part of Kagoshima prefecture's Satsuma peninsula.

Excavation was conducted in 2004-05, with more than 35,000 stone implements recovered. A source of the shale used for the stone tools was discovered nearby at the same time as the excavation, and the site drew attention as a locus of intensive stone tool production utilizing that source.

Age and contents of the tool assemblage

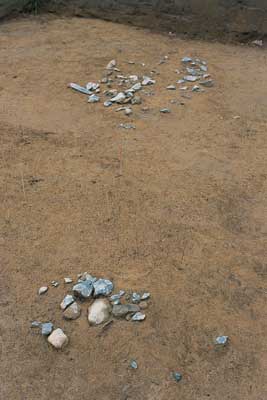

The stone tools recovered from the site divide broadly into four phases. Among these the second cultural stratum (20,000 - 18,000 BP), in which pyramidal-point stone tools are found, and the third cultural stratum (17,000 - 16,000 BP), yielding small knife-shaped tools, draw interest. Stone tools are recovered in dense fashion in both cultural strata, with concentrations discovered that are thought to be tool manufacturing sites, but for the third cultural stratum in particular a total of 12 such concentrations were found, and active tool production utilizing the rich source of stone is inferred.

Reconstructed! A Paleolithic tool-making workshop

In what manner were the stone tools made?

Because the stone used as raw material is split in making stone tools, when the remaining fragments are pieced together in the manner of a three-dimensional puzzle, the original form can be reconstructed (as refitted material).

The more than 770 items total of refitted materials from the Miyanoue site are one of the leading examples for western Japan in terms of both quantity and quality. Not only can the techniques and process of stone tool manufacture be clarified in their entirety from these materials, when the order that flakes were struck and their locations of recovery are compared, the way that tools or the persons making them moved within the site in the manufacturing process can also be reconstructed. This wealth of refitted materials, showing the entire shape of the tool-making workshop, serve as extremely valuable pieces of evidence.

What the gaps in refitted materials show

When the refitted materials are observed, gaps can be seen at various places. The flakes that occupied those spaces were used as blanks for tools, and probably taken away from the site. Meanwhile, in addition to the shale available nearby the site, small amounts of stone material from places 10 - 30 km distant were used at Miyanoue. Perhaps people of the Paleolithic period moved from these source areas while hunting, and stopped at the Miyanoue site in order to make tools. Miyanoue is also deeply intriguing as a site where these cycles of Paleolithic people's livelihood can be understood. (Magome Ryōdō)

How the "movement" of tools is seen

Stone tools are made in the following steps: (1) processing the raw source stone, (2) preparing the core for flaking, (3) producing flakes to serve as blanks for tools, (4) making finished tools, (5) selecting the by-products, and (6) disposing the waste. By tracing the recovery locations of refitted flakes, it can be seen how the stone tool moved about with each task involved. Analyzing in detail the distribution of refitted materials in conjunction with the stone tool manufacturing process, the activities of Upper Paleolithic people participating in tool production become visible. Looking at refitted materials from the third cultural stratum, as the shapes of the raw stones utilized and the manners of flaking show subtle differences, it is gathered that several tool makers worked in coordination at the task.

Adapted from Hakkutsu sareta Nihon rettō 2011 [Excavations in the Japanese Archipelago, 2011] (Bunkachō [Agency for Cultural Affairs], ed., Asahi Shimbun Publications, 2011).

Photos courtesy of Kagoshima Prefectural Archaeological Research Center